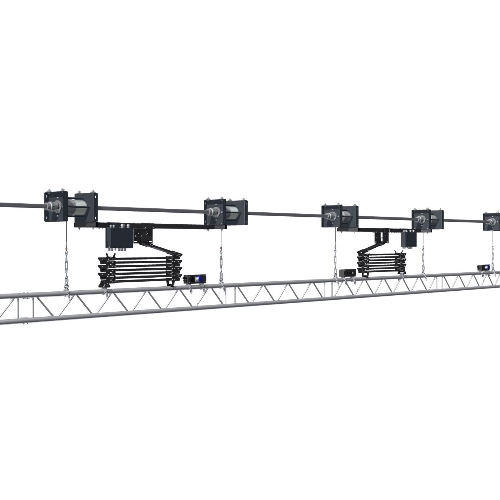

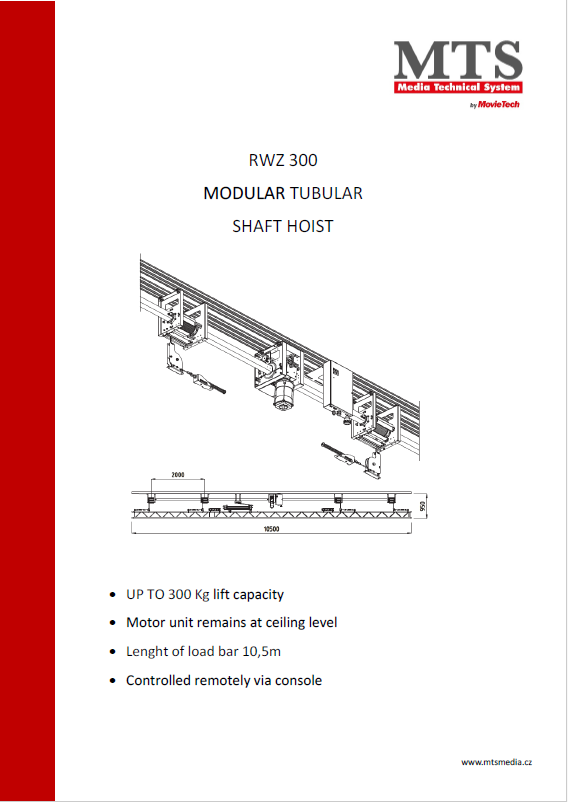

RWZ 300 / RWZ 400 / RWZ 600

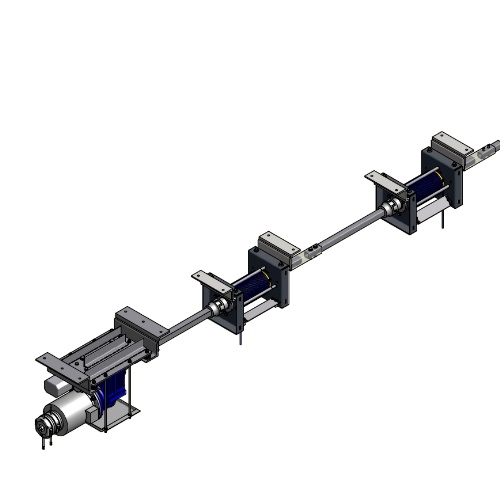

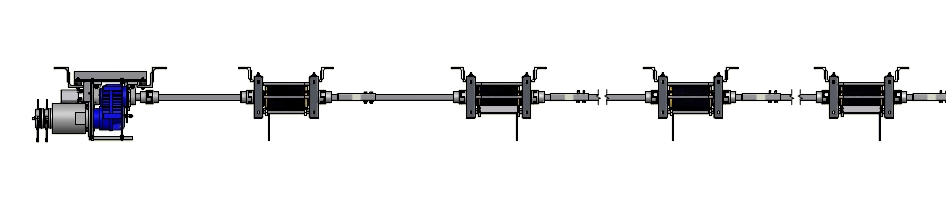

The tubular shaft hoist a modular design

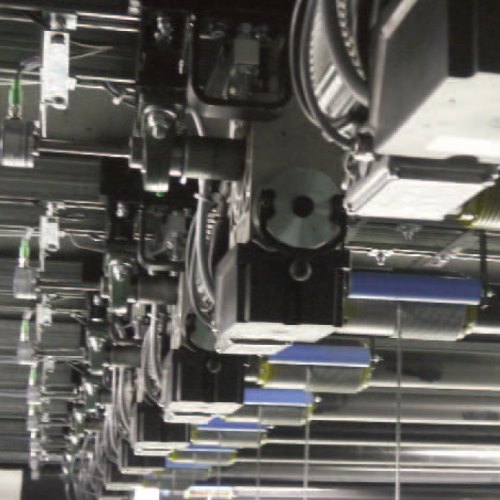

The MTS tubular shaft hoist system offers ready-to-install assemblies in a modular design. The system has been specially developed for use in event venues and can be assembled from just a few modules.

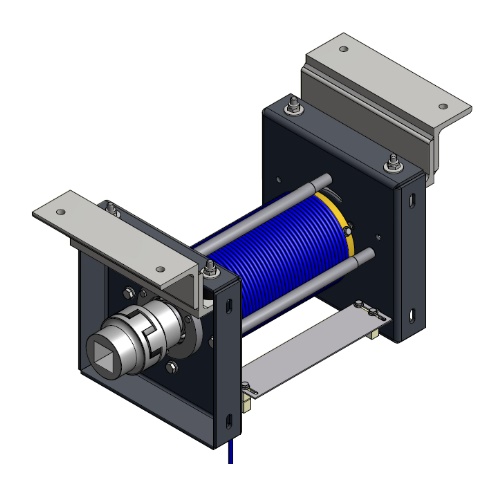

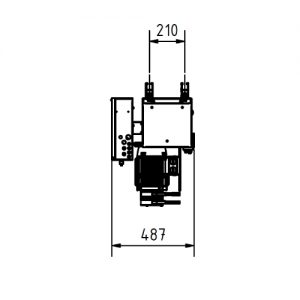

- motor unit (optional for 300kg, 400kg or 600kg)

- tubular shaft

- cable units

- load bar

- mounting flanges

- control unit

In this way, individual requirements are met in an economical manner. The patented cable units ensure excellent running stability and running safety even with slack or rope. The MTS tube shafts can be equipped with up to 16m stroke and are thus suitable for almost every application in studio and stage.

The MTS products fulfill all relevant safety regulations such as the stricktest german safety norms DGUV regulation 17 (formerly BGV C1, formerly VBG 70) as well as DIN 56950-2 (formerly DIN 15560).

The highlights at a glance:

- modular construction system

- very silent cable pull

- safe rope run

- Payload up to 300kg / 600kg

Describtion:

Standard or extras

The modular system allows a large number of standard types, which we can cut down on a millimeter scale as required. On request, we will be happy to provide you with: additional cable runs or special constructions.

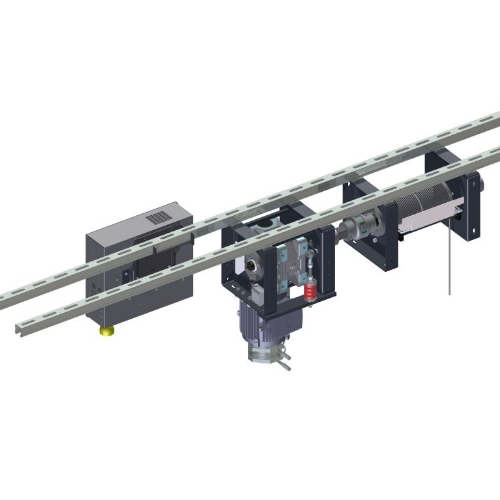

Each winch element is equipped with an extremely load-bearing steel cable (d = 6mm) and can carry up to 180kg payload. In a specific application, the number of winch elements, the lifting height and the choice of the appropriate drive unit determine the payload of the overall system.

Safety

Two independent, hand-held brakes ensure increased safety. The pressing device holds the steel cable in any position or e.g. in the case of percussion or slack rope securely on the rope drum. The RWZ system is tested by TÜV. The MTS – Media Technical System tube shafts conform to the relevant safety regulations DGUV regulation 17 (formerly BGV C1, formerly VBG 70) as well as DIN 56950-2 (formerly DIN 15560).

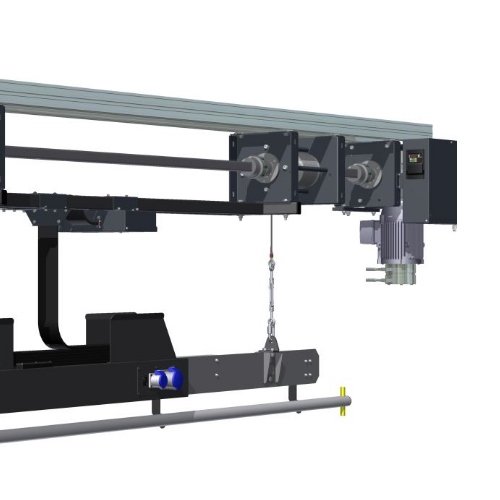

Control

The plug-in contactor control ensures the constant speed as well as the final cut-off at the top and bottom position in the standard version. Optionally, a steplessly adjustable lifting speed as well as a control for several RWZ systems can be realized in group or individual driving. The control can take place via a desk, a switching bulb or optionally via remote control or PC. On request, the tube shaft couplings can also be integrated into an existing control system after consultation.

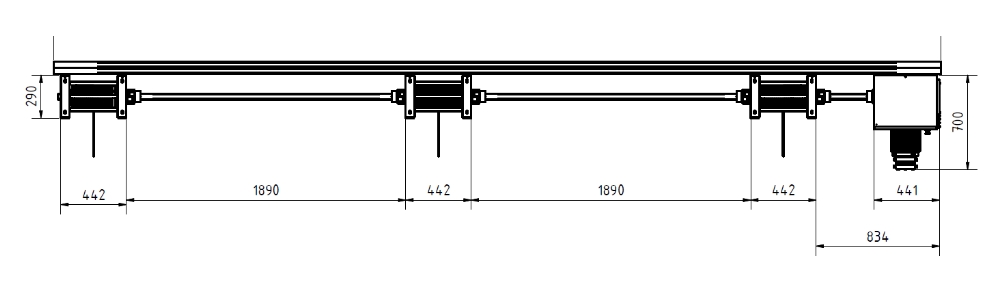

Installation

The uncomplicated installation can usually be undertaken by your own in-house technology. This saves time and money. With a small footprint, the self-supporting construction will require two to four mounting points on the ceiling or wall depending on the length of the system. With the known cable suspension, load bars can be easily attached and disconnected.

Delivery form and scope of delivery

The tube shafts are delivered as preassembled, complete assemblies. In order to simplify handling, we supply elements from 6.0 m in split design. During assembly, the halves are then mechanically connected. The scope of delivery also includes a complete technical documentation of the system. With the known cable suspension, load bars can be easily attached and disconnected.

Technical specifications:

- Load bar: Ø 48.0 mm (standard)

- Carrying means: Steel rope d = 6mm

- Excerpt: up to max. 16000 mm

- Max. Load capacity: 300/600 kg

- Power and data supply optional

- Dynamically self-locking gearbox

- Slack wire rope break detection

- Operating limit switch up / down

- Emergency up / down switch

- DGUV regulation 17 (formerly BGV C1, former VBG 70) as well as DIN 56950-2 (formerly DIN 15560)

- Load bearing by means of clamps or pipe wagons

- Reserve technical changes.

Downloads:

Download all operating instructions, service manuals and programming files

Equipment:

Art.Nr. 3509 005 FCP PRO Studio Contol Unit

Art.Nr. 350.026 RFS-TC 4

Art.Nr. 350.900 FCP 900

Do you need any help? Just contact our sales team for more information:

Felix Kastl

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: f.kastl@movietech.de

Sales:

MovieTech, ABC-Products, MTS

Ralf Merkle

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: r.merkle@movietech.de

Sales:

MovieTech, ABC-Products, MTS

Kenneth Shore

Tel: +41 (0) 91 68 30 606

Fax: +41 (0) 91 68 23 195

Email: kenneth.shore@tiscali.it

Sales:

MovieTech, ABC-Products, MTS

Mounir Lahlou

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: m.lahlou@movietech.de

Sales:

MovieTech, ABC-Products, MTS