Manual pantographs SZM 25-60

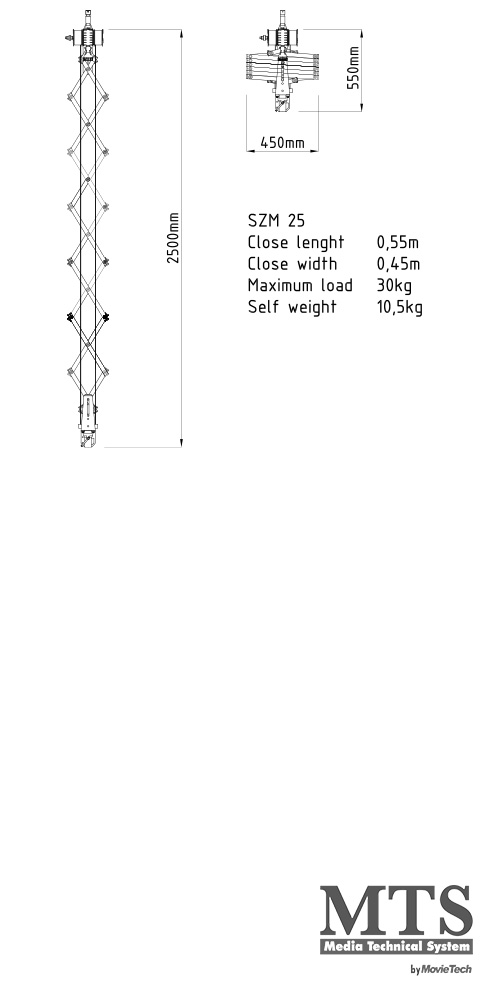

SZM 25 – Art.Nr. 312.250 – 2,5m 30kg

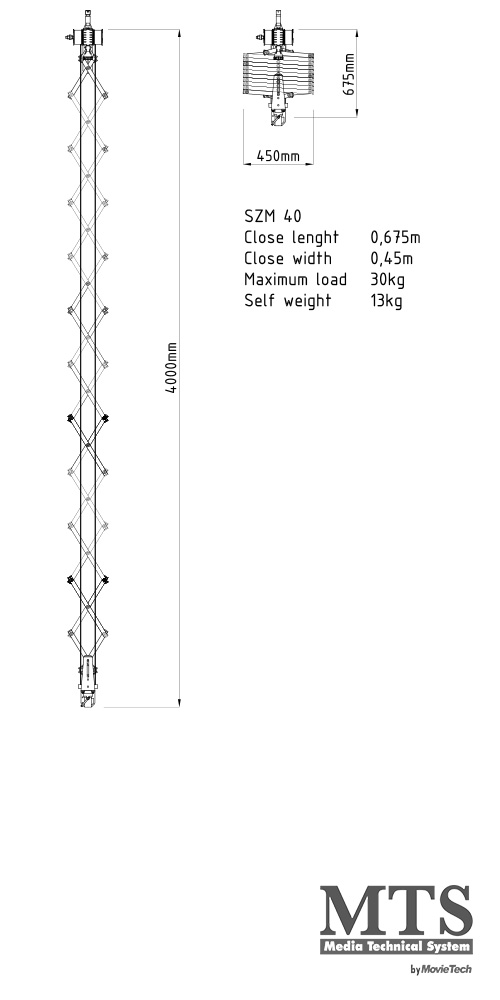

SZM 40 – Art.Nr. 312.450 – 4m 30kg

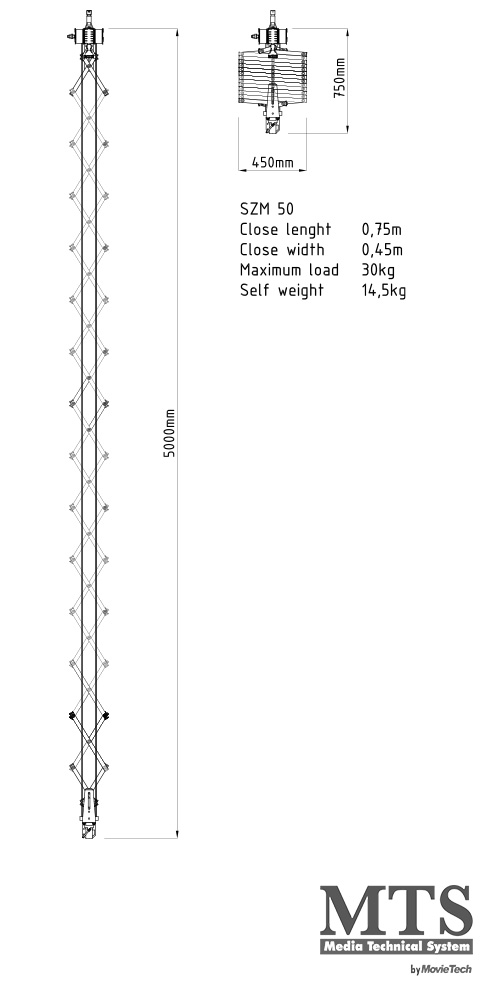

SZM 50 – Art.Nr. 312.500 – 5m 30kg

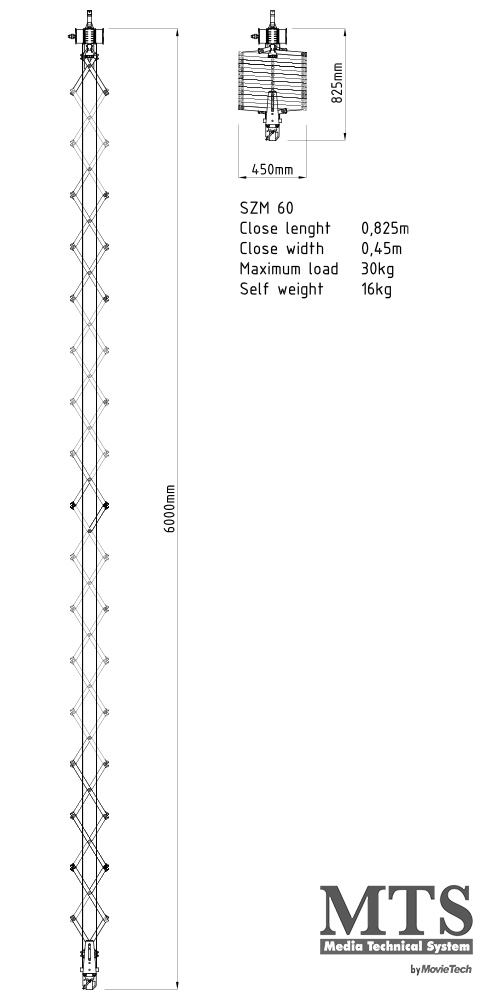

SZM 60 – Art.Nr. 312.600 – 6m 30kg

Special lengths on request

Manual MTS pantographs

MTS’s manual pantographs are used to precisely position lighting, audio and video equipment.

The abbreviation SZM 25-60 stands for cable pantograph (manual) with extensions between 2500mm and 6000 mm.

The load capacity of these pantographs is up to 30 kg.

Customized adaptations of the lifting devices can be made at any time upon request.

Description

Through the use of pantographs, each luminaire can be individually controlled. This allows an enormous flexibility in the design of the light.

The MTS pantographs are made of aluminum rectangular profiles with particularly high mechanical strength and precision. In the retracted state, the overall height is minimized. The extension of the pantographs reaches up to 6m depending on the design. If a larger stroke is required, the use of MTS telescopes or MTS Hoist systems should be used.

The powder-coated scissors of the MTS pantographs ensure a maximum of stability. Two steel ropes with a diameter of 2.8 mm serve as support. The drive is self-locking, maintenance-free and technically oversized. The guide elements on the upper and lower holders of the scissors ensure precise pull-out and pull-in with minimal torsion and radial play. The large bending radius of the suspension system prevents wear and cable breakage. The power and data feed to the lower end of the pantograph is safely guided outside the scissors by and held in place via durable plastic clips. A Schuko connection is provided as standard, alternatively a CEE socked is available. In addition it is possible to proviede a DMX outlet at the lower end of the pantograph.

The load can be attatched via a standardized DIN TV capsule with eyelet for a safety cable. The manual pantographs can reliably lift and lower loads up to 30kg. A 28 mm DIN TV spigot is provided for the upper attachment. This allows the pantograph to be mounted to various trolleys.

The up/down movement of the pantographs can be induced via the bell by means of rod control (by hand or by machine).

The MTS pantographs fulfill all relevant safety regulations such as the stricktest german safety norms DGUV regulation 17 (formerly BGV C1, formerly VBG 70) as well as DIN 56950-2 (formerly DIN 15560)

The highlights at a glance

- toolless maintainance; all maintainance points can be directly viewed

- proven design

- 30kg payload

- DIN TV spigot for upper attachement

- in accordance to the strictest safety regulations DIN 56950-2 and DGUV V17

- up to 6m drop

General advantages of panthographs

- Flexibility through individual height adjustment of each headlight

- low height in a retracted condition

- economically

General disadvantages of pantographs

- limited stroke (up to about 6000m)

Technical specifications

- Stroke length: up to max. 2500/4500/5000/6000 mm

- Suportin cables: 2 x d = 2mm

- Power outlet: 16 A Schuko socket (alternatively CEE 17)

- max payload: 30 kg

- Standard cable: 3x 2.5 mm²

- DMX XLR 5 socket (optional)

- Transmission: dynamically self-locking drice, 1:20

- Upper attachment: DIN TV spigot, d = 28 mm

- Load atachment: DIN TV socket, d = 29 mm

- Operated via operating pole SBV or motorized pole MSB 400

- safey standards: DGUV V17 (former BGV C1/ VBG 70) and DIN 56950-2 (former DIN 15560)

Accessories

Manual trolley

pole operation

Art. Nr. 315.348 LW-R48

Art. Nr. 315.349 LW-R60

Art. Nr. 315.100 LW-IP 100

Art. Nr. 315.120 LW-IP 120

Art. Nr. 315.140 LW-IP 140

Art. Nr. 315.160 LW-IP 160

Art. Nr. 315.330 LW- H 100

Art. Nr. 315.332 LW- H 200

Art. Nr. 315.333 LW- H 300

Art. Nr. 315.340 LW- H 400

Art. Nr. 315.350 LW- H 500

Art. Nr. 315.360 LW- LAS1

Art. Nr. 315.370 LW- LAS1/2

Art. Nr. 315.335 LW- LASS2

Art. Nr. 315.300 LW- LASS3

Art. Nr. 315.365 LW- TV100

Art. Nr. 430.000 MSB 400 Power unit for rod control, adaptable for SBV system, without extension

Art. Nr. 430.001 SBV 100 (1m)

Art. Nr. 430.002 SBV 150 (1,5m)

Art. Nr. 430.003 SBV K Winch

Art. Nr. 430.004 SBV E Rod endng piece

Do you need any help? Just contact our sales team for more information:

Felix Kastl

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: f.kastl@movietech.de

Sales:

MovieTech, ABC-Products, MTS

Ralf Merkle

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: r.merkle@movietech.de

Sales:

MovieTech, ABC-Products, MTS

Kenneth Shore

Tel: +41 (0) 91 68 30 606

Fax: +41 (0) 91 68 23 195

Email: kenneth.shore@tiscali.it

Sales:

MovieTech, ABC-Products, MTS

Mounir Lahlou

Tel.: +49 (0) 89 43 68 91 3

Fax: +49 (0) 89 43 68 91 55

Email: m.lahlou@movietech.de

Sales:

MovieTech, ABC-Products, MTS